Industrial Hygiene Testing

Comprehensive industrial hygiene testing and laboratory analysis ensuring safety through rigorous workplace exposure monitoring.

View Services Our accredited industrial hygiene testing services based in Houston, TX AGT Labs, deliver trusted solutions to protect worker health and ensure full OSHA, NIOSH, and EPA compliance. We specialize in IH testing for Asbestos, Silica (RCS), Lead, Metals, Dust, Mold & Bioaerosols, VOCs, IAQ, Noise, and Heat Stress.

Our Industrial Hygiene Testing Services

Asbestos Testing

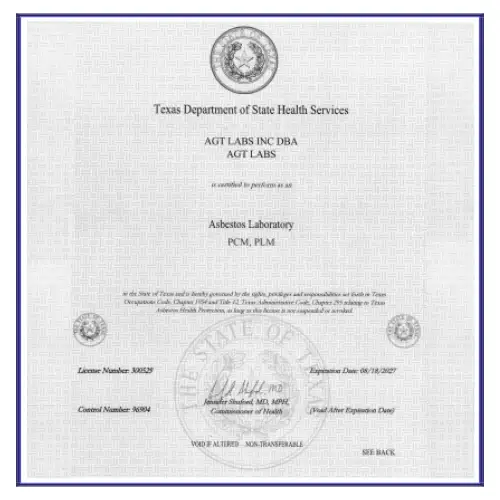

We provide comprehensive testing for both Friable and Non-Friable Asbestos Materials and airborne fibers, ensuring strict compliance with OSHA (29 CFR 1910.1001 / 1926.1101) and EPA regulations. IH testing for asbestos clearance include bulk sampling using Polarized Light Microscopy (PLM) and advanced air monitoring via Phase Contrast Microscopy (PCM) for clearance and Transmission Electron Microscopy (TEM) for definitive identification.

BTEX / VOCs / TO-15 & TO-17

For organic vapor analysis, particularly within petrochemical and manufacturing environments, we utilize specialized industrial hygiene testing services for indoor air quality, including charcoal tubes, passive badges, and Tedlar bags/Canisters. This service targets BTEX (Benzene, Toluene, Ethylbenzene, Xylene), monitors Total Volatile Organic Compounds (TVOC), and analyzes specific air pollutants using EPA Method TO-15.

Dust, Total & Respirable

We perform monitoring for general workplace particulates, classified as Particulates Not Otherwise Regulated (PNOR). Our service involves Gravimetric Analysis via air sampling to accurately measure both the total mass of dust and the smaller, more hazardous Respirable Dust fraction that can penetrate deep into the lungs, ensuring compliance with general industry OSHA PELs.

Indoor Air Quality (IAQ)

Comprehensive IAQ surveys combining real-time sensors and laboratory analyses to measure CO₂, PM₂.₅/PM₁₀, TVOCs, formaldehyde, temperature, and humidity. Ideal for offices, schools, and healthcare facilities our industrial hygiene testing services for indoor air quality help diagnose complaints, verify ventilation, and optimize occupant health.

Inorganic Chemicals / Reactive Gases Testing

We provide real-time and time-weighted average monitoring for highly hazardous inorganic gases and vapors, including Hydrogen Sulfide (H2S), Carbon Monoxide (CO), Ammonia (NH3), Ozone (O3), and Chlorine Gas (Cl2). We utilize both Direct Read Instrumentation and Impinger/Treated Filters for laboratory-based compliance analysis providing reliable Industrial Hygiene testing for toxic gas exposure against OSHA PELs.

Lead Testing ( Air, Paint, & Surfaces )

Our lead services address industrial and construction hazards, including monitoring for Airborne Lead dust and assessing bulk materials. We use X-Ray Fluorescence (XRF) for rapid Lead in Paint surveys and perform lead wipe testing for clearance following abatement, ensuring adherence to the stringent OSHA Lead Standard through professional IH assessments.(29 CFR 1910.1025) and EPA RRP rules.

Metals and Hexavalent Chromium (Cr VI)

Beyond general welding fumes, we specialize in assessing exposure to highly toxic metal compounds. This includes industrial hygiene testing for Hexavalent Chromium (CrVI) monitoring for trace metals like Beryllium and conducting specific sampling and analysis for Hexavalent Chromium (CrVI), using dedicated methods (like OSHA Method ID-215) to comply with the specific OSHA CrVI Standard (29 CFR 1910.1026).

Metals in Air & Welding Fume Testing

To protect welders from the complex mixture of airborne contaminants, we conduct targeted air monitoring for Welding Fumes Metals such as Iron, Manganese, Nickel, and Cadmium. Samples collected on Mixed-Cellulose Ester (MCE) filters are analyzed using techniques like ICP or AA spectrometry, with all work calibrated to OSHA PELs for individual fume components.

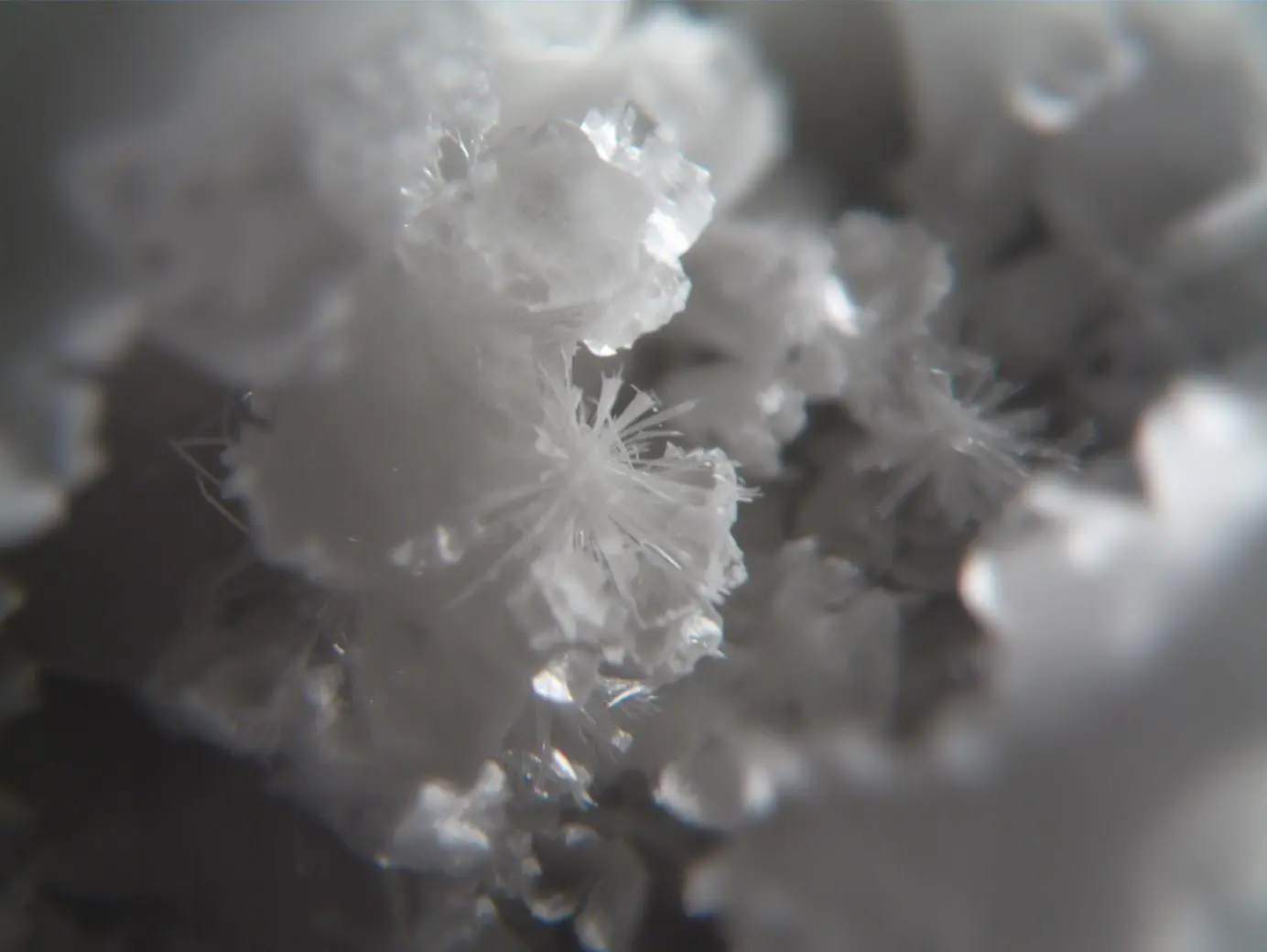

Mold & Bioaerosols

Our experts conduct detailed Indoor Air Quality (IAQ) Investigations to identify sources of moisture intrusion, assess building systems, and evaluate exposure to biological contaminants like Aspergillus, Penicillium, and Stachybotrys. We employ various Air and Surface Sampling techniques, including spore traps, tape lifts, and swabs, to adhere to state regulations.

Noise & Heat Stress Screening

Preliminary noise dosimetry and WBGT heat stress screenings to identify high-risk tasks and zones. We provide rapid field surveys, exposure mapping, and recommendations for hearing conservation, administrative controls, and heat stress mitigation strategies.

Respirable Crystalline Silica (RCS)

To meet the stringent OSHA Respirable Crystalline Silica Standard, we offer specialized exposure monitoring for crystalline forms like Alpha Quartz, Cristobalite, and Tridymite. Our process involves personal air sampling using cyclones and filter media, which is then analyzed using sophisticated methods like X-Ray Diffraction (XRD), typically following NIOSH 7500/OSHA ID-142 procedures.

Solvents, Acids, and Alkali

We assess employee exposure to a wide array of reactive and corrosive agents such as Acetone, Isocyanates, Formic Acid, and Sodium Hydroxide. Monitoring is achieved through Chemical-Specific Sampling, employing specialized collection media like sorbent tubes, impingers, or passive badges, with analysis tailored to meet specific OSHA PELs providing customized industrial hygiene testing services for solvents and acids.

Sampling & Analysis

We provide advanced industrial hygiene sampling and analysis for workplace air, surfaces, and materials. Our procedures ensure precision, reliability, and compliance with OSHA, NIOSH, and EPA industrial hygiene standards.

Industries We Serve

Manufacturing

Noise surveys, air quality monitoring IH, welding fumes, solvents, and ergonomics assessments.

Construction

Silica dust monitoring, asbestos management, and heat stress assessments.

Healthcare & Labs

Exposure assessments for chemicals, anesthetic gases, and sterilization agents.

Energy & Utilities

Hydrocarbon and chemical exposure monitoring and power generation noise control.

Government

Indoor air quality investigations in offices and schools and hazard training.

Food & Beverage

Industrial hygiene testing services for processing safety and cleaning chemical monitoring.

Why Choose Our Laboratory?

Regulatory Compliance

Our methodologies strictly adhere to OSHA, NIOSH, and EPA industrial hygiene standards, ensuring your results meet all legal safety requirements.

Rapid Turnaround

We understand that safety cannot wait. We offer flexible TAT options including same-day and 24-hour rush services for critical projects.

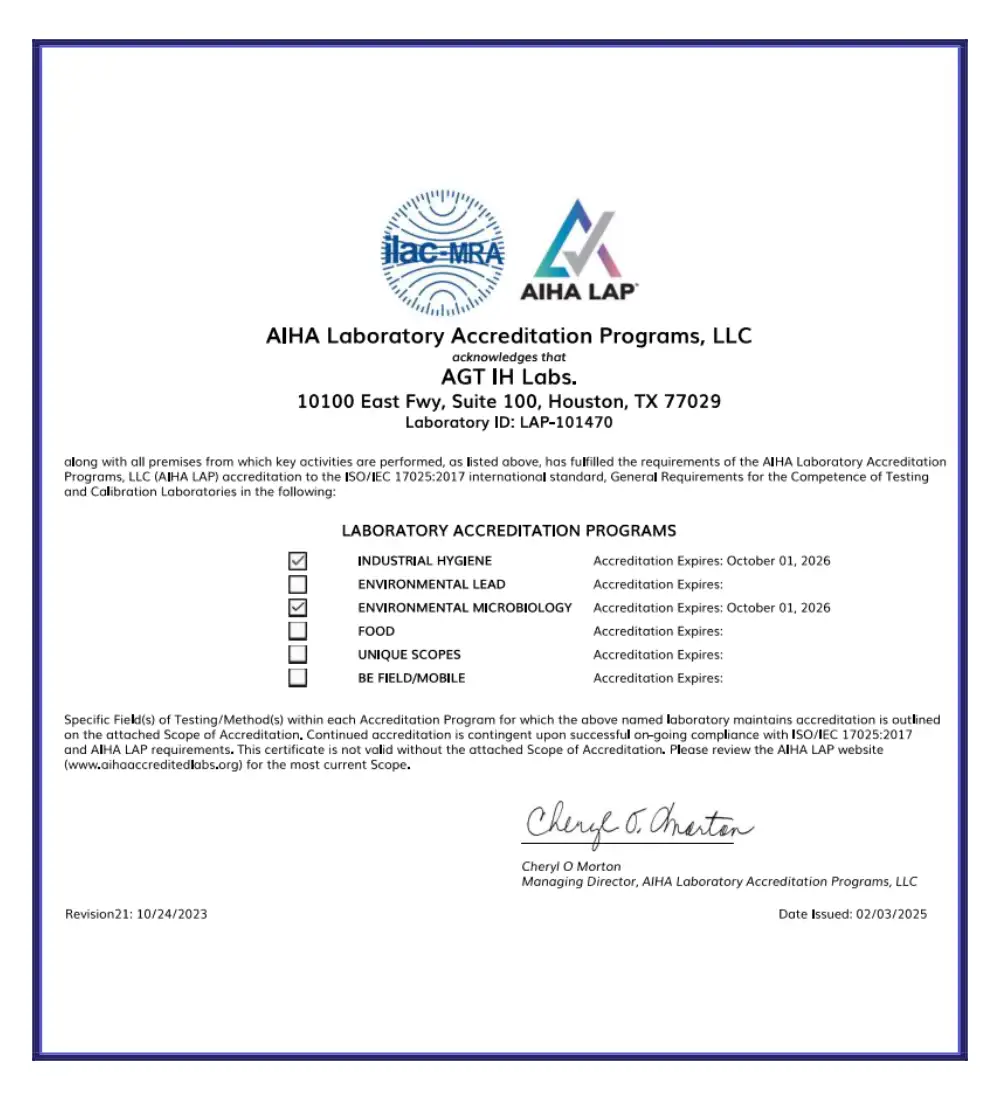

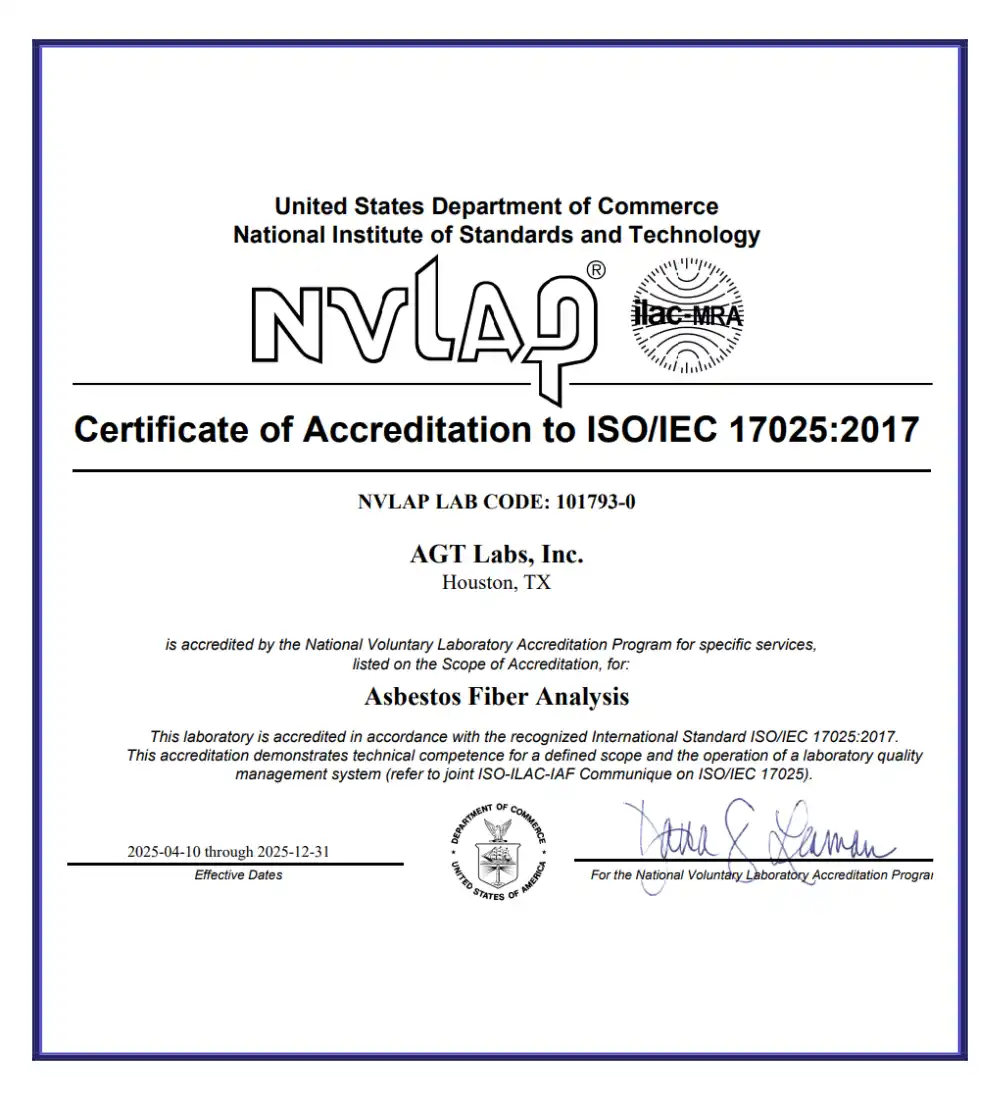

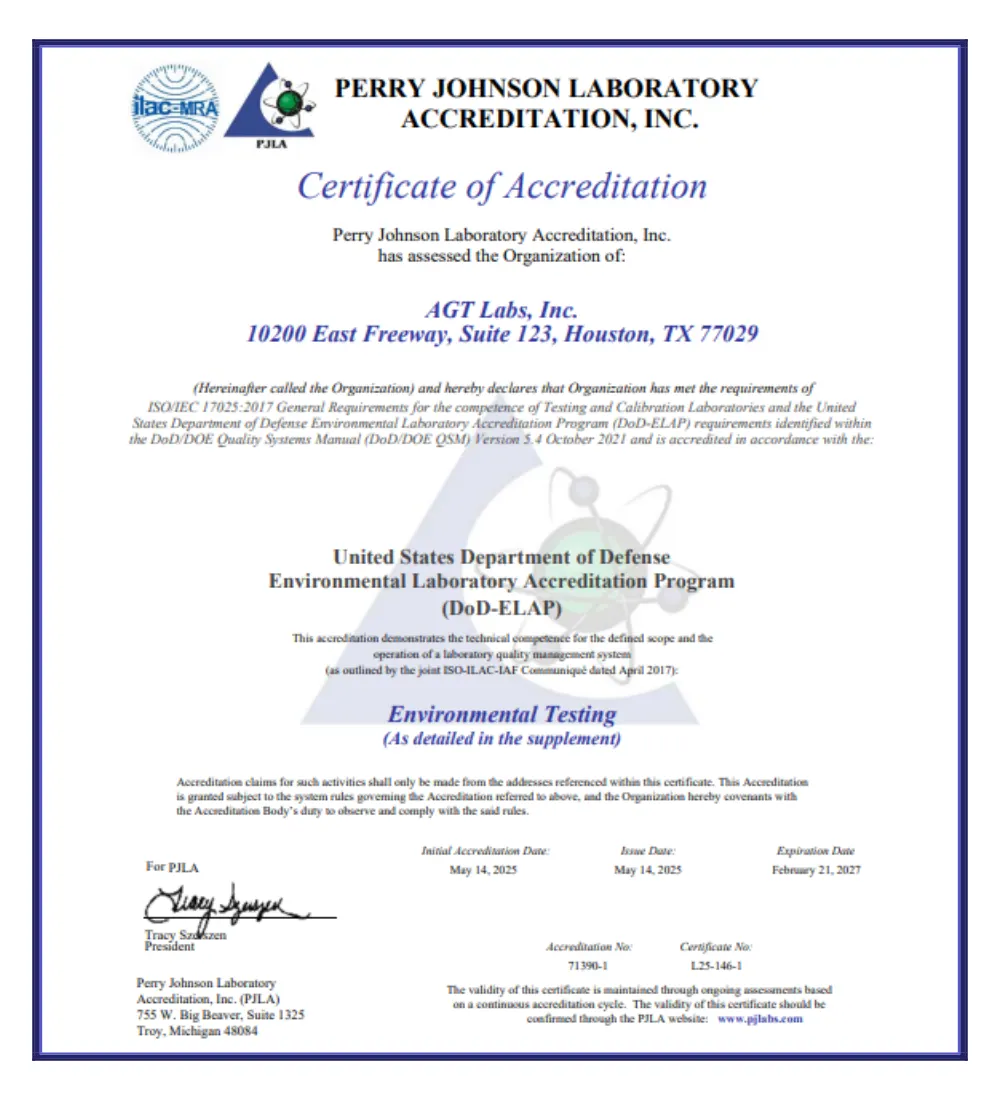

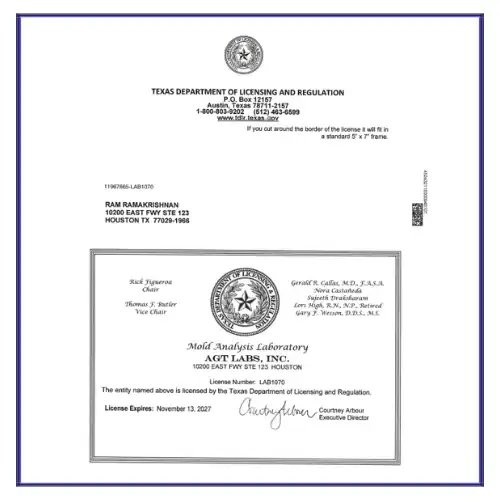

Certified Excellence

With AIHA-LAP and NVLAP accreditations, our technical competence is verified industrial hygiene testing.

Our Systematic Approach

Consultation

Define project scope and identify specific hazards requiring monitoring.

Sampling

On-site data collection using calibrated professional-grade equipment.

Analysis

Rigorous laboratory testing at our accredited Houston facility.

Reporting

Detailed analysis reports with data defensibility for OSHA compliance.

Frequently Asked Questions

1. Where is your laboratory located?

AGT Labs’ main office is located at:

10200 East Freeway, Suite 100, Houston, TX 77029

We also operate service centers in Harlingen and the South Texas region.

2. What are your operating hours?

| Day | Business Hours |

|---|---|

| Monday – Friday | 7:00 AM to 6:00 PM (CST) |

| Saturday | Closed |

| Sunday | Closed |

Emergency & After-Hours: 713-453-6090

3. Do you offer courier and sample pickup?

Yes. Coordinate via your Project Manager at (713) 453-6090 or info@agtlabs.com.

Service Areas: Houston, Bay City, Freeport, Lake Jackson, Victoria, and Harlingen.

4. What is the typical turnaround time?

Standard analyses are typically completed within 7+ business days.

We offer expedited industrial hygiene testing turnaround times specified in each project estimate.

5. When do rush charges apply?

Rush surcharges are calculated based on turnaround speed:

- 1 Business Day: 100% surcharge

- 2 Business Days: 75% surcharge

- 3 Business Days: 50% surcharge

- 4 Business Days: 25% surcharge

Note:

- • If asbestos samples are unusable, additional preparation fees may apply.

- • For bulk PLM testing, separate layers are billed individually.

6. Can sample kits be shipped to us?

Absolutely. With 5 business days’ notice, we provide outbound shipping via UPS Ground or similar cost-effective carriers.

7. Do you provide sampling media and equipment?

Yes. With 5 business days’ notice, we can supply specialized sampling media and equipment required for your project.

Get in Touch With Us

Your opinion matters. We would like to hear from you.

Contact us today to learn more about our industrial hygiene testing programs and how we can help ensure a safer, compliant workplace.